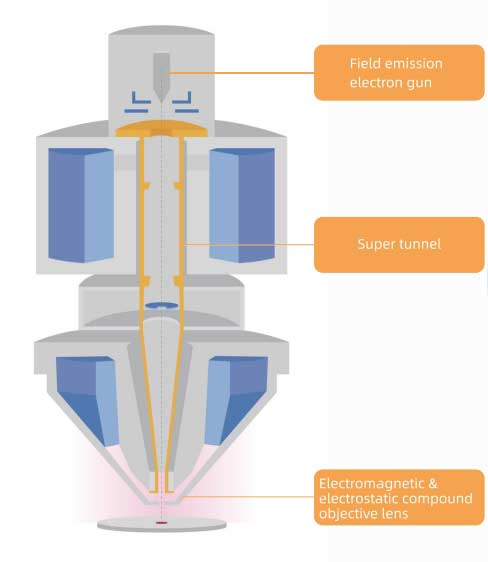

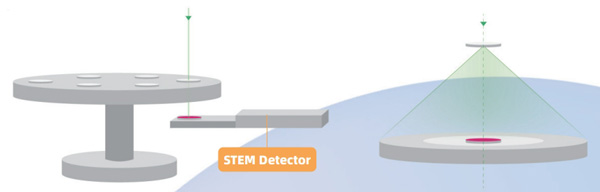

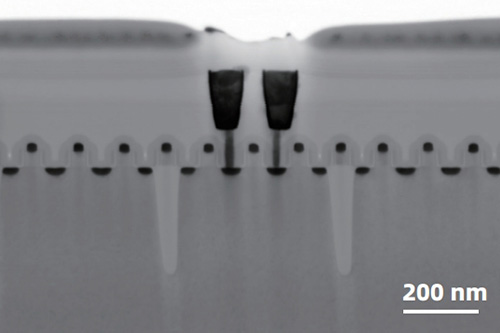

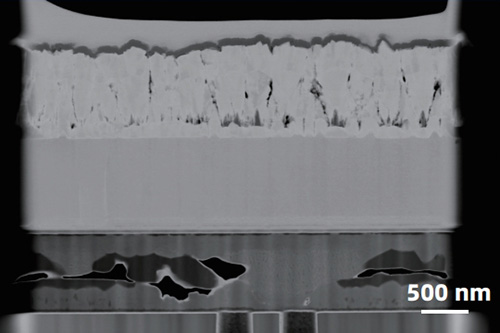

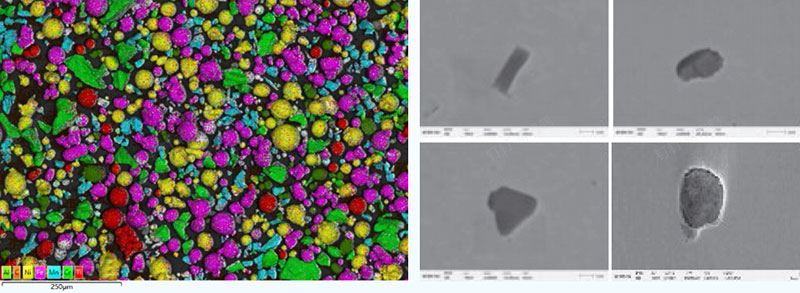

1. "Super Tunnel" electron optics column technology/in-column beam deceleration

Decrease spatial charging effect, ensuring low voltage resolution performance.

2. Crossover-free in the electron beam path

Effectively reduce lens aberrations and improve resolution.

3. Electromagnetic & electrostatic compound objective lens

Reduce aberrations, significantly improve resolution at low voltages, and enable observation of magnetic samples.

4. Water-cooled constant-temperature objective lens

Ensure the stability, reliability, and repeatability of the objective lens performance.

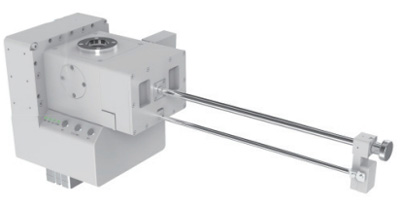

5. Variable multi-hole aperture switching system by electro-magnetic beam deflection

Automatic switching between apertures without mechanical motion allows fast switching among various imaging modes.