♦ Embedded test computer, safe and stable. 10-inch capacitive touch screen, tablet control experience.

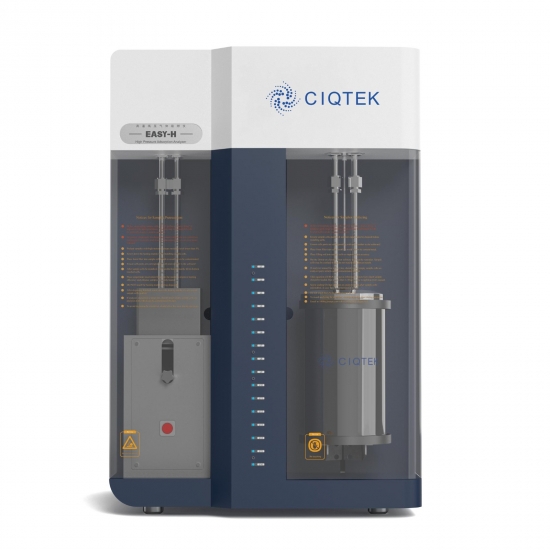

♦ The micro-welded stainless steel sample tube and the VCR metal surface are sealed and connected to maintain a reliable sealing performance in high temperature and high pressure; high-precision test data can still be obtained for small sample loading.

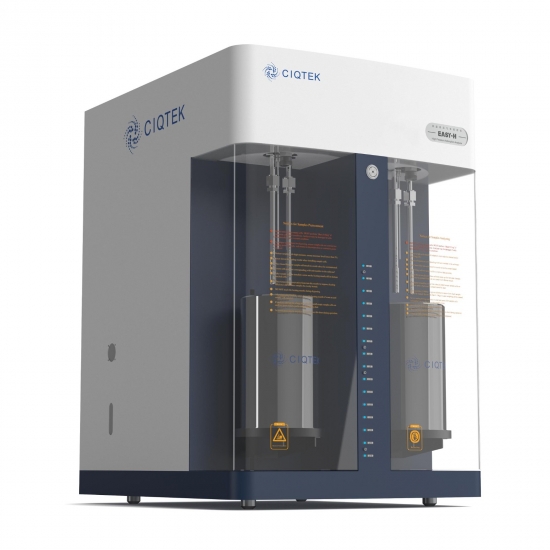

♦ The protective safety door can prevent safety accidents caused by accidental contact with low-temperature liquid nitrogen and eliminate the impact of environmental factors on the test.

♦ Heating packages up to 550°C (1022°F) for ease of use; the higher temperature heating device can be equipped with a ceramic fiber integrated hard rigid heating furnace.

♦ The ball screw integrated lifting system, controlled by the stepper motor, overcomes the shortcomings of common screw types easy to jam, and so on.

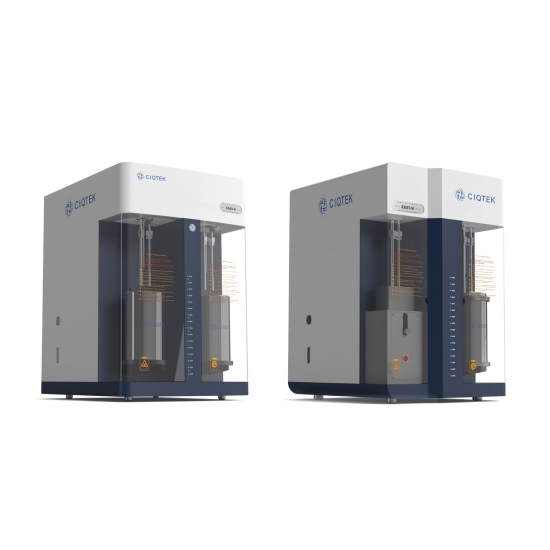

♦ For EASY-H 2210: Independent 2 sample processing ports can be performed simultaneously with sample testing to improve testing efficiency.

Digital pressure measurement and data acquisition system

- The pressure and temperature sensor with digital output has twice the accuracy of similar products with analog output and stronger anti-interference ability.

- Industrial standard RS485 or RS232 communication mode. Sensors are added on demand on the communication bus, with high scalability.

- High stability digital quantity pressure sensor, extremely low-pressure temperature drift can still maintain the low-pressure fluctuation under high pressure, which is conducive to improving the test accuracy.

- The sensor can output the digital quantities of temperature and pressure at the same time, which facilitates the secondary correction of the pressure-temperature drift software.

Stainless steel micro welding pipeline system for high pressure and vacuum

- 316L stainless steel thick-walled high-pressure micro-welded pipeline system with compact pipeline connections and small dead volume space.

- VCR interface parts with metal surface seal overcome the problem of self-outgassing of O-ring seal under low vacuum.

- The supporting VCR interface pneumatic valve eliminates the measurement error caused by local heating of the electron magnetic valve. The service life is up to 5 million times, which improves the stability and service life of the instrument.

- The electropolished method of pipe wall in the whole system ensures an air leakage rate of 1*10-10 pa.m3/s under high vacuum conditions.

Splashproof stainless steel micro welded sample tube

- Stainless steel micro welded sample tube, with a standard volume as low as about 10mL, can place rock/coal pillar, and a large capacity sample tube can be customized.

- A primary gas barrier system is set in the sample tube, and a secondary detachable gas filtration system is set at the sample tube joint. The double protective measures can effectively prevent the sample from accidentally entering the ultra-clean valve body and improve the service life and reliability of the instrument.

- For small amounts of splash-prone samples, the patented triple anti-splash system is designed to ensure the safety of high-pressure testing.

World-leading data accuracy and authority recognition

- The micro standard chamber (reference chamber) combined with a high sealing pipeline system. Using a small amount of sample (mg level to several grams level) can achieve the same accuracy as the test results of tens of grams of sample used by traditional instruments, and the small amounts of samples can effectively improve the test efficiency.

- The fully automated test process can eliminate errors through manual operation, and unattended test mode can run continuously for a long time (more than a week); measurement errors are dynamically eliminated by the software during the test, and no secondary error elimination operation on the data after the test, which ensures the consistency and reliability of test results by different operators.

- The products are highly recognized by customers worldwide and the test data are used in papers published in prestigious journals.

By simulating the isotherms and adsorption and desorption kinetics of coal bed methane (CBM) or shale gas (methane) under the high pressure and temperature conditions of the coal and shale samples extracted from underground, the reserves of CBM or shale gas and the ease of extraction can be predicted, and the feasibility and economic value of extraction can be evaluated.

By simulating the gas pressure and temperature requirements of hydrogen storage materials in the application environment, the PCT curves, desorption kinetics curve, and desorption hydrogen platform pressure of hydrogen storage materials are measured, providing a powerful tool for the research of hydrogen energy storage and application development.

> EASY-H 2210 & 2420 extended molecular pump system

The molecular pump system can be expanded on demand to further increase the ultimate vacuum to meet the requirements for the detection of gas-sensitive samples.

It can be optional when purchasing the instrument or can be added later according to the needs of research and development and production to flexibly meet the needs.

It adopts a high-performance maintenance-free molecular pump, with a high ultimate vacuum and strong long-term stability.

> EASY-H 2210 & 2420 extended low-temperature test system

Extend the testable temperature range of high-pressure adsorption to -196°C (-320.8°F, liquid nitrogen temperature) or other coolant temperatures to meet the requirements of high-pressure and low-temperature testing.

The special sample tube is resistant to low-temperature and high-pressure environments, and the special design reduces the volatilization of cryogenic coolant.

> Test principle:

Static volumetric method

> Main functions:

Adsorption/desorption isotherms measurement at any temperature from room temperature to 550°C (1022°F), Gibbs supercritical adsorption measurement; Gas adsorption and desorption rate measurement (i.e. adsorption desorption kinetics); PCT isotherm measurement, TPD temperature programmed desorption and hydrogen discharge temperature platform measurement, hydrogen absorption and discharge pressure platform measurement, hydrogen absorption and discharge cycle experiment (fatigue test); Coal adsorption and analytical capacity measurement, adsorption and resolution rate measurement; Gas adsorption constant a and b values; Customizable coal simulation constant pressure adsorption and desorption capacity measurement function.

> Test accuracy:

Repeatability error is less than ±3%

> Test temperature:

Room temperature to 550°C (1022°F) (higher temperature can be customized); -196°C (-320.8°F) to room temperature (optional for low-temperature test function module).

> Temperature control:

The temperature control range can reach any temperature from room temperature to 550℃(1022°F), with a temperature control accuracy of 0.1℃(32.18°F);

The software integrates the temperature PID control function, which can realize the precise control of any multi-stage heating rate;

The temperature control process is set and executed automatically through the software interface, without the need for an external thermometer, which eliminates the tedious manual operation and possible misoperation of multi-stage temperature control and improves the automation of the instrument.

> Test pressure:

Continuous adsorption and desorption in the pressure range of vacuum ~ 200 Bar; The number of experimental equilibrium pressure points and pressure value can be flexibly set by software.

> Data processing:

Langmuir model regression isotherm, Langmuir maximum adsorption constant L and adsorption pressure constant B measurement (a and b values of coal adsorption); Langmuir correction model loading-ratio correlation regression (LCR) isotherm; three-parameter Langmuir regression isotherm.

> Sample numbers:

For EASY-H 2210: Two samples tested alternately and two of the analysis ports and two of the analysis ports can perform cycle test /TPD test/hydrogen absorption and desorption kinetics tests; Two Samples' degassing treatment.

For EASY-H 2420: Four analysis ports and two of the analysis ports can perform cycle test /TPD test/hydrogen absorption and desorption kinetics tests.

> Sample tube:

Standard 10mL stainless steel micro welding sample tube. Sample tubes of other volumes can be customized upon request.

> Test gas:

High purity nitrogen, CO2 or others (Ar, Kr, H2, CH4, etc. optional)

> Pipeline structure:

316L stainless steel thick-walled pipeline, high-pressure micro-welded pipeline system, the main pipeline using micro-welding technology to seal the connection, effectively reduce the dead volume space, and improve test accuracy;

All-metal VCR connection, safe and reliable, and easy to install or remove the pipeline connection.

> Vacuum pump:

Two-stage vacuum pump, optional extended molecular pump.

> Control system:

The high-pressure pneumatic valve with a VCR interface can realize automatic on/off control within the pressure range of 200 Bar, sealability is up to 1x10-10 Pa.m3/s, service life is up to 5 million times;

The programmable logic controller system with high integration and strong anti-interference ability improves the stability and service life of the instrument.

> Protective measures:

Equipped with an external protection door, eliminates the high-temperature injury to the experimental operator. More importantly, it effectively reduces the impact of external airflow changes on the test, greatly improving the test stability and accuracy of the instrument.

> Safety measures:

The original EASY-H progressive inflation and exhausting technology can realize automatic inflation and exhausting, safe and reliable, eliminating the danger of manual operation of high-pressure gas and reducing the damage caused by large differential pressure shock to the pressure sensor.